THE UGEARS MÉRIHOBUS TRIMARAN - Assembly Overview by Cedric

FTC Disclaimer: The author of this article received a FREE model from UKidz LLC/ UGears.us. He wasn’t compensated in any other ways. The article previously appeared at Malceo.fr in French.

A few weeks ago, Ukidz LLC, a distributor of the Ugears brand in the United States, contacted me. My previous article interested them, and they asked to publish it on their site: ok for me! The story could have ended there, but then they offered to write an article on a model of my choice, which they shipped to me.

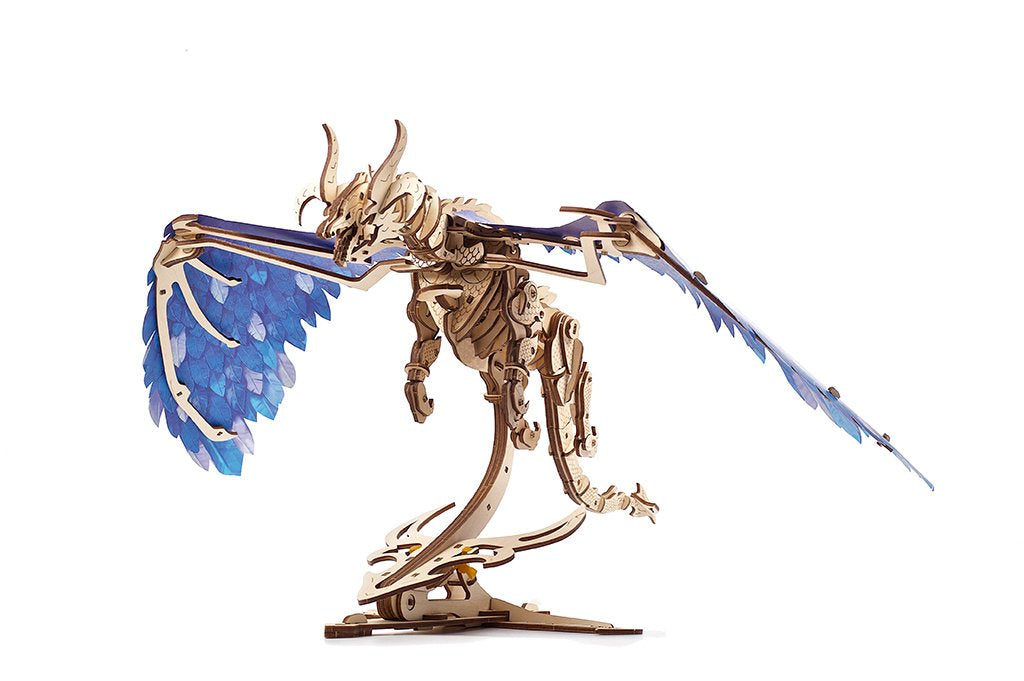

Let's be clear: not only was it flattering for an amateur writer to be republished, but it also promised to be a fun project! The UGears catalog is extensive, and it wasn’t easy to choose just one model.

Contents of the box

- 5 plywood boards

- 5 rubber bands

- several wooden sticks

- Several meters of white wire

- A mainsail, a staysail, and a flag

- 2 squares of sandpaper

- 1 piece of candle

- Assembly instructions

The compact packaging is of great quality, and the design is clean. The instruction booklet is translated into several languages, including French. The instructions are mainly made up of clear diagrams and drawings, in color, explaining step by step. Plan to use a cutter (to cut the sticks to the correct length) and tweezers.

Let's go for 12 to 15 hours of reflection

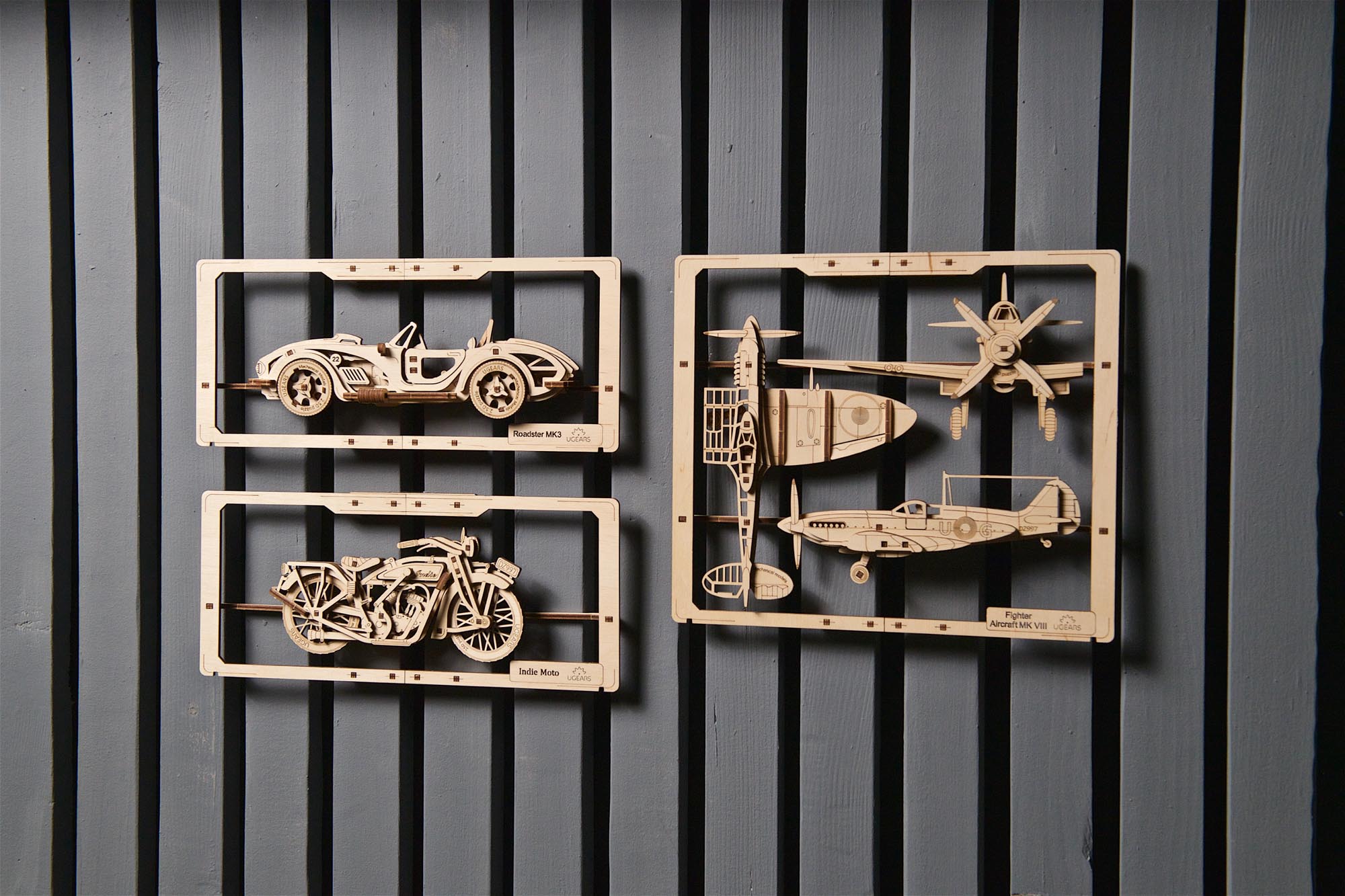

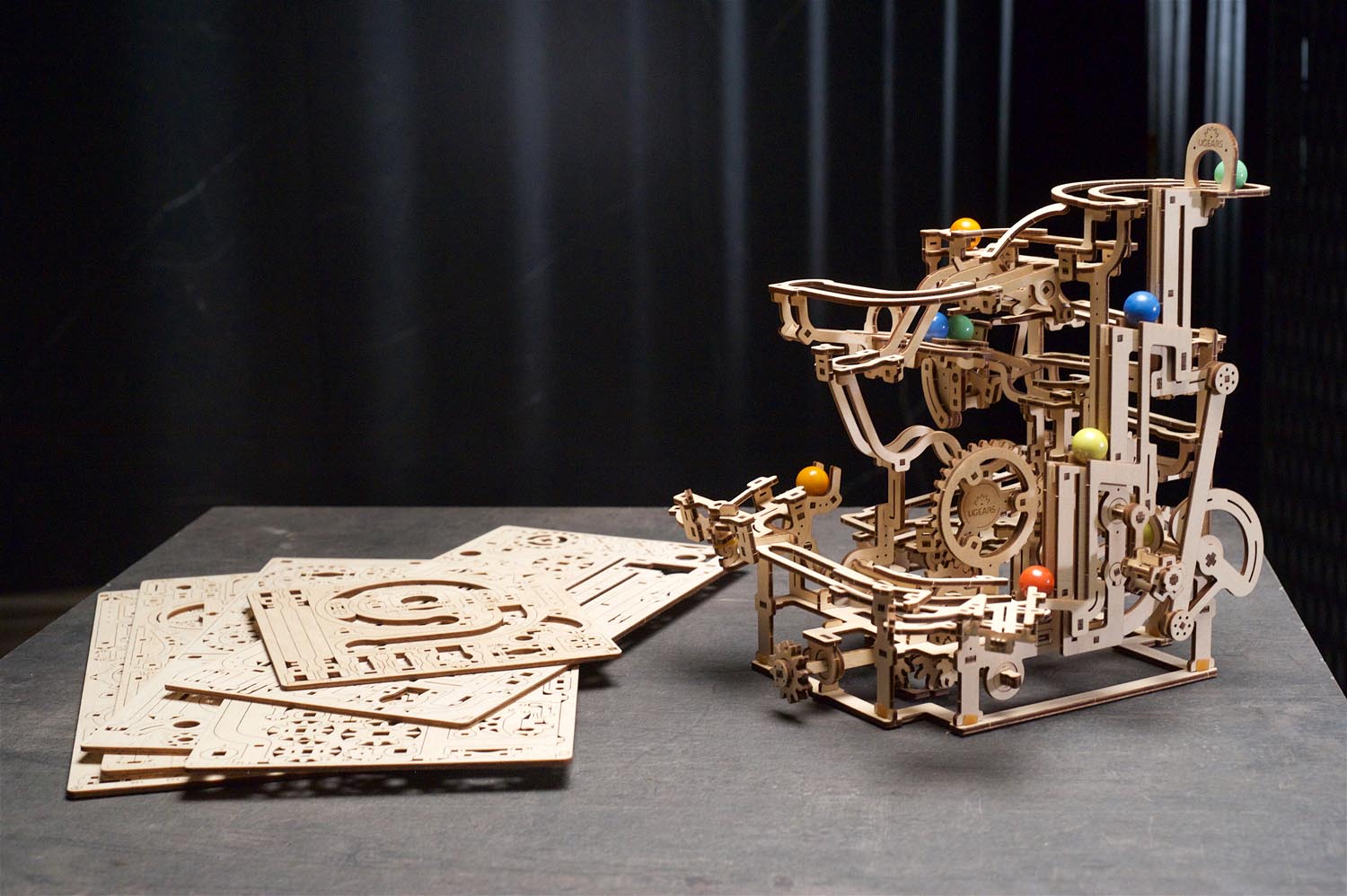

Ugears offer 3D models, all in wood, without glue or screws.

The model contains 240 pre-cut laser parts. The process guarantees high cutting precision which is essential for exemplary assembly. The pieces will be assembled using the classics of carpentry: half-timber, low-cut, tenon-mortise with or without crucial opening.

All the starting pieces are "flat": they are pre-cut in plywood boards 5mm thick. Their assembly makes it possible to obtain a 3-dimensional model, which feels like a bit of magic. You can guess that this is a result of hard work and numerous tests by the manufacturer.

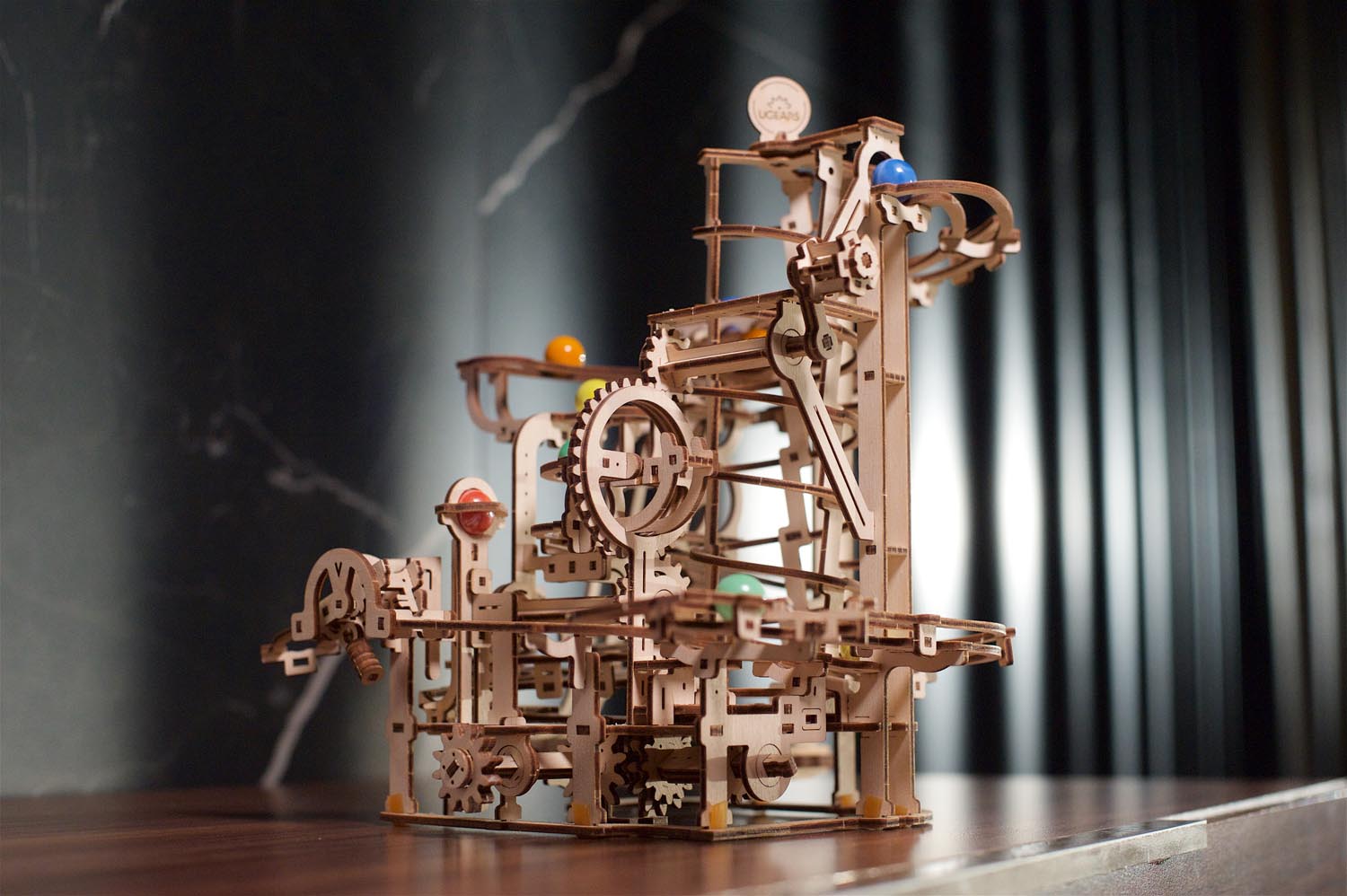

Eye for detail

The search for realism is visible throughout the construction. Attention to detail has been taken far, very far. I am thinking of the lifeboat propeller: six mm long, three mm wide!

This desire for realism impacts the proper functioning of certain "moving" parts. For example, tied at its two ends on the drum winch, the white thread should unwind from one end and wind up simultaneously on the other.

Looks easy enough on the photo, but I couldn’t make it work. Is it a problem? No, in my opinion. Of course, it would be very satisfying to make all the mechanisms work. Still, after a few moments of "playing,” the Mérihobus trimaran becomes above all a beautiful decorative object: "you touch with your eyes.”

Can it be improved? I think yes. I have no particular knowledge of seamanship (the art of tying knots, among others) and would appreciate additional diagrams of the best ways to secure and tighten threads.

Careful: Fragile

Most of the pieces are thin and brittle, which significantly contributes to the general aesthetics of the trimaran. Still, it makes the assembly “delicate,” all the more so as it is sometimes (often!) necessary to apply some force to fit the elements together.

This difficulty is not a defect. It contributes to the uniqueness of the model. What is the best solution to succeed in the assembly without breaking anything? What is the best way to hold the model? How am I going to hold the model to get a good grip? Which part is strong enough to press on? Which side do you have to go through to pull the wire through the skeleton of the hull?

In short: model making is a hobby for the calm and the meticulous.

Is sanding cheating?

According to the instructions, the sandpaper is reserved for a few gear elements: pinions, rings, etc.

I have regularly used it to "reduce" very slightly the thickness of the tenons or to make a tiny bevel on the angles. Even small, this adjustment seemed essential to me to fit certain parts together without forcing them excessively. A light passage allows you to remove the tenth of a millimeter that makes the difference and avoids accidents: the part that forces, gives way, and breaks.

Bottom line

The Mérihobus trimaran, like the UGM-11 truck, is a beautiful object. Its construction is stimulating when you like finesse and precision. The assembly requires more than 12 hours of meticulous work, which fully justifies the price (around 45 € / $50).